Background Abstract background Help and Advice

abstract light bokeh background

INNOVATION TO ENHANCE YOUR MOBILITY

At Michelin, innovation means creating new value recognised by our users.

It has played and will continue to play a key role in your business's growth and performance.

MICHELIN TECHNOLOGIES

We place innovation at the core of our global strategy. Whether born in the laboratory or proven on the track, innovation is a critical catalyst for development, competitiveness, and the enduring resilience of your business.

The Michelin Technology Centre leads this charge, employing over 6,000 specialists across 350 fields of expertise—including world-class researchers, engineers, and site-testers. With more than 10,200 active patents worldwide, our R&D investments focus on what matters most to Australian businesses: creating tyres that are safer, longer-lasting, more profitable, and significantly more sustainable over the long haul.

Edito michelin casing Help and Advice

Carcasse Michelin Poids Lourd

Background factory visit 244 Help and Advice

pneu michelin

Edito chemistry Help and Advice

Background ecosystem michelin group Corporate fleet

Edito michelin casing Help and Advice

Carcasse Michelin Poids Lourd

THE TYRE CASING

A large number of casing-related innovations deliver greater tyre durability and make a direct contribution to keeping your fuel consumption under control.

INFINICOIL technology

MICHELIN DURABILITY AS THE MILES TICK BY

We have introduced a continuous steel belt—reaching lengths of up to 400 metres—wrapped around the entire tyre structure to provide unparalleled stability throughout its service life. When combined with our advanced architecture, this technology ensures industry-leading endurance, even wear patterns, and superior retreadability for Australian hauliers.

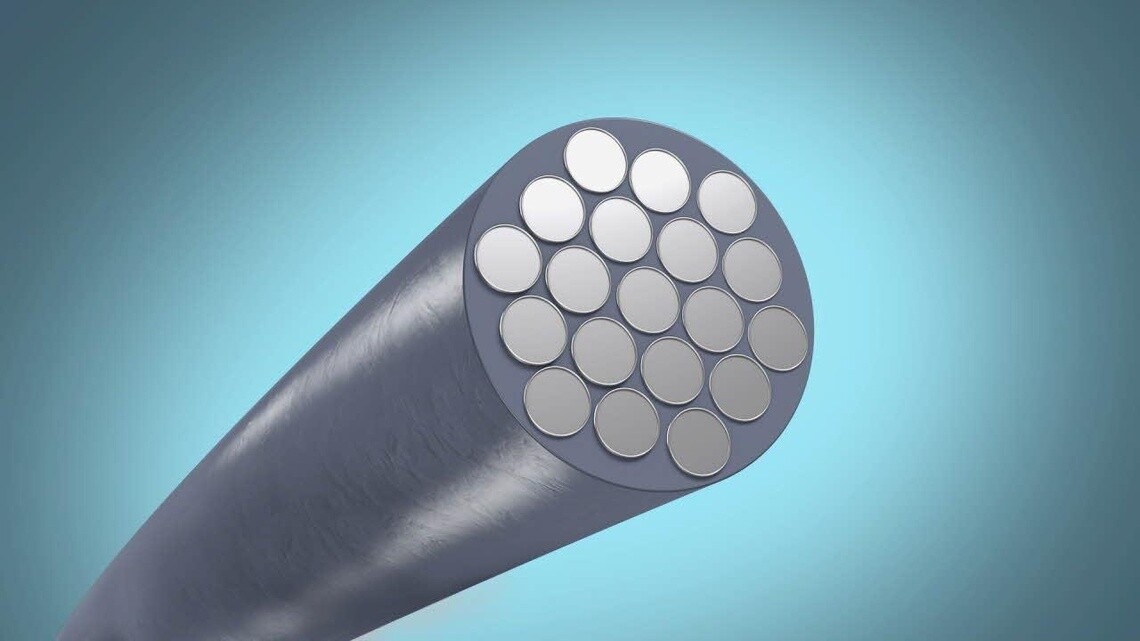

POWERCOIL technology

MICHELIN ENDURANCE WITH IMPROVED ROLLING RESISTANCE

This represents a new generation of high-tensile, robust steel casing cables that significantly reduce tyre weight. This reduction leads to improved thermal endurance and reduced rolling resistance, translating to better fuel economy on long-haul Australian routes.

Picto image powercoil technology 1 Help and Advice

Pneu Michelin technologie

DURACOIL technology

A REINFORCED BEAD FOR GREATER ROBUSTNESS:

We manufacture high-quality products built to go the distance. DURACOIL reinforces the tyre-to-wheel interface, utilising high-quality nylon to protect the bead area and provide exceptional stability for the bead toe. This reinforcement dramatically improves casing endurance and enables multiple retread lives, maximising your asset's value.

The right pressure, at the right moment: Central Inflation System

In Australian agribusiness, maintaining low pressure is vital in the field to minimise the equipment footprint and mitigate soil compaction. Conversely, higher pressure is essential for highway transit to ensure stable handling and reduce tyre wear. Thanks to our Central Tyre Inflation System (CTIS), operators can enjoy all these benefits instantly from the comfort of the driver’s seat.

tractor equipped with central tire inflation system to ensure traction on mud and limit soil compaction

Presseveranstaltung

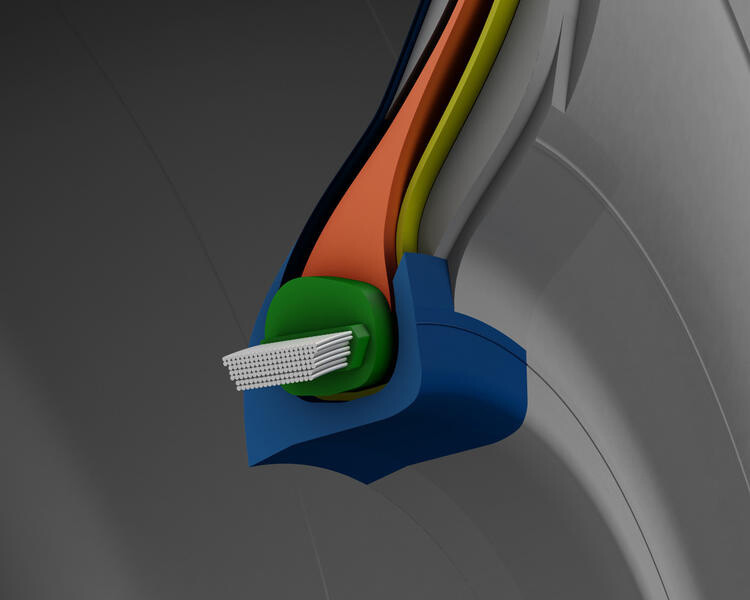

B2 technology

DEAL WITH EXTREME CIVIL ENGINEERING CONDITIONS

In Australian mines, quarries, and construction sites, machinery and tyres are regularly pushed to their absolute limits. Michelin’s exclusive B² Technology reinforces the bead area, significantly extending service life under high-torque applications.

The tyre-to-rim interface is under immense stress during heavy hauls or high-torque manoeuvres. MICHELIN tyres featuring B² technology utilise a wide metal bead wire to increase the contact area with the rim. This enhances bead strength and eliminates rim slippage. Dig more and carry more—B² technology delivers up to 20% more torque*, making your heavy equipment more productive than ever.

*Internal study compared with standard MICHELIN tyres. Specific values vary by size

Picto b2 technology Help and Advice

NRF technology

COPE WITH THE EXTREME CONDITIONS OF UNDERGROUND MINING

Engineered for the harshest conditions, NRF technology improves resistance through:

-

Two additional plies added to the structure, featuring cross-woven nylon cords for maximum robustness.

-

New cables in the working plies designed for enhanced impact resistance and superior protection against oxidation.

Background factory visit 244 Help and Advice

pneu michelin

TREAD

Cutting-edge technologies for our tyre tread, with patterns that evolve and adapt as tyres wear to boost service life and performance.

REGENION technology

MICHELIN GRIP, MILE AFTER MILE

Featuring self-regenerating tread blocks produced via advanced 3D metal printing, REGENION ensures consistent grip throughout the tyre's life. As the tyre wears, new grooves emerge to maintain traction and mobility. In recognition of this breakthrough, the Michelin engineers behind REGENION won the prestigious European Inventor Award.

Edito chemistry Help and Advice

MATERIALS

Cutting-edge technologies for our tyre tread, with patterns that evolve and adapt as tyres wear to boost service life and performance.

CARBION technology

MICHELIN LONGEVITY, DAY AFTER DAY

This innovative material results from a unique mixing process where tread components are blended in a liquid state, creating a more uniform and resilient compound. This advanced material significantly increases the mileage performance and longevity of the tyre.

SILICION technology

MORE SILICA for REDUCED FUEL CONSUMPTION

By integrating a high percentage of silica into the tread rubber, Michelin has set new benchmarks for rolling resistance. This allows Australian operators to achieve substantial fuel savings without sacrificing tyre longevity or safety.

Background ecosystem michelin group Corporate fleet

BEYOND THE TYRE

With related services or new types of products, MICHELIN tyre innovations make tyres safer and longer-lasting, and increase profitability.

Edito michelin x tweel ssl all terrain Construction and Industry

MICHELIN X® TWEEL® Airless Technology

NO MAINTENANCE. NO COMPROMISE.

The MICHELIN X® TWEEL® is a revolutionary airless radial unit that replaces the traditional tyre and wheel assembly. High-strength, flexible polyurethane spokes join the tread to the wheel, eliminating punctures and the need for pressure maintenance. This technology virtually eliminates machine downtime and offers unparalleled convenience and comfort for operators in construction, handling, and agribusiness.