3D modeling of a tractor and a slurry trailer equipped with a remote inflation system (CTIS)

CENTRAL TYRE INFLATION SYSTEM:

Adjust Your Tyre Pressure on the Move Central Tyre Inflation System

WHY SHOULD I ADJUST MY TYRE PRESSURE?

Importance of CTIS when planting

Frequent use of agricultural machinery causes soil compaction, limiting aeration, reducing water infiltration, and hindering nutrient absorption. This can lead to lower crop yields, increased disease susceptibility, and costly decompaction efforts.

Reduce your costs up to 10%

Adopting lower tyre pressure in your fields is essential to reduce equipment footprint, limit rut formation, and soil compaction.

Correct tire pressure is vital when farming

No matter your vehicle type, the correct tyre pressure is essential to improve operational efficiency. This will help enhance handling, limit rolling resistance, reduce fuel consumption, and reduce tyre wear.

Simulate the best pressure for your vehicle, usage, and specific needs with our AgroPressure Tool.

WHAT ARE THE ADVANTAGES OF CENTRAL TYRE INFLATION SYSTEM (CTIS)?

In many agricultural applications, changing tyre pressure several times throughout the day is ESSENTIAL.

Several factors impact optimal tyre pressure: vehicle type, load, pressure, and speed.

As a farmer, you may have to change tractor tyre pressure several times on your farm, depending on the crop.

With the Central Tyre Inflation System you can conveniently control tyre pressure from your seat.

Without CTIS, you would need to manually adjust the pressure of each tyre, which is time-consuming.

WHY USE A CENTRAL TYRE INFLATION SYSTEM?

Increase your yield up to 4%

Increase your productivity

Up to 4% increase in productivity due to improved traction*

Increased traction, less slippage, and reducing fuel consumption.

Up to 10% fuel savings in field use when adjusting your tire pressure

Reduce your costs

Up to 10% fuel savings in field use when adjusting your air pressure in tractor tyres*

The increased surface area of the tyre generates less soil pressure, avoiding compaction and preserving the agronomic yield to its maximum potential.

Up to 33% decrease in the pressure applied to soil

Protect your soil

Up to 33% decrease in the pressure applied to soil when adjusted pressure is used**

Better pressure management generates less tyre wear, less fuel consumption, and less working time allowing you to get better use out of your machine.

30% reduction in traction loss with CTIS

Decrease wheel spin

Up to 30% reduction in traction loss when actively using CTIS*

Don't let a rainy season decrease your output. With CTIS, inclement weather delays are a thing of the past.

Thanks to the Central Tyre Inflation System, you can enjoy these benefits on demand from the driver's seat!

HOW DOES CENTRAL TYRE INFLATION SYSTEM WORK?

Central Tyre Inflation System uses sensors, valves, and a control unit to determine your optimal tractor tyre pressure for the terrain and improve your driving conditions. The system then activates valves to inflate or deflate tyres accordingly.

You will be able to adapt air pressure in tractor tyres on the move, all from the comfort of your seat, ensuring that you maintain the correct pressure exactly when you need it.

COMPATIBILITY WITH AGRICULTURAL MACHINES

Central Tyre Inflation System is compatible with all your agricultural machinery whether they are slurry tankers, manure spreaders, and planters. You can implement it on:

- Any vehicle

- Any tyre brand or range

- Any configuration

HOW THE CENTRAL TYRE INFLATION SYSTEM IS CONNECTED TO YOUR TRACTOR

Designed and produced by our affiliated company PTG, an expert of more than 30 years in Central Tyre Inflation System technology.

8 ptg logo affiliated michelin company based in germany specialized in ctis

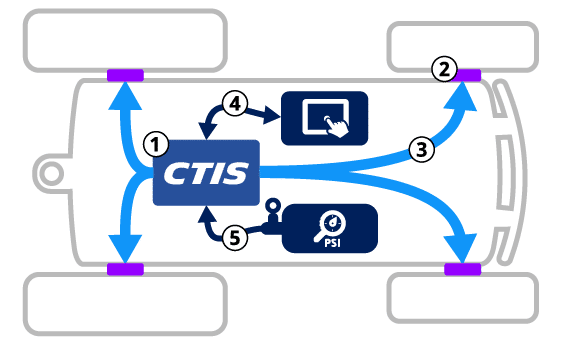

7 schema of ctis components for an implementation on a tractor

CTIS is composed of:

- one central control system

- one rotary union by the wheel

- air lines to link between the CTIS case and each tyre

- one connection between CTIS and the terminal (ex: ISOBUS) in your cab

- one connection between CTIS and your tractor air system

HOW TO CONTROL TYRE PRESSURE FROM THE INTERFACE

ISOBUS terminal example

The interface on your terminal is very easy to manage:

- Quickly inflate or deflate tyres, even on the move

- Select your preferred working terrain (road or field) and your load (from full to empty)

- Choose the axle

- Parameter a set of high and low pressures per axle

- More than 18 different configurations are available

Could be fully integrated with the ISOBUS terminal

DID YOU KNOW?

MICHELIN Ultraflex technologies help improve the benefits of CTIS

PNEUS COM A TECNOLOGIA MICHELIN ULTRAFLEX

ULTRAFLEX logo on the sidewall of a tire

Enhance your CTIS experience by using tyres that are designed to operate at low pressure.

Explore Tyres that works best with PTG CTIS

FREQUENTLY ASKED QUESTIONS (FAQs)

We will need some additional information to give you a quote, please contact us to proceed with a custom quote by clicking HERE.

Almost all agricultural vehicles can be fitted with CTIS, our main market is tractors and trailers in general but we can fit our systems on sprayers, seeders, combines.

Most of the time it takes between 10 and 12 hours per axle but installation will vary by equipment. Please contact our CTIS for installation advice HERE.

Our CTIS is a safe system based on strict quality and safety standards. Most OE brands have approved the use of CTIS on certain equipment. Please contact our CTIS expert with specific manufacturer questions HERE.

For CTIS to work, an air compressor (such as an air brake compressor) is necessary. If your equipment isn't equipped with one, any CTIS dealer can get one for you.

No problem! We offer an alternative digital solution to help manage CTIS on your equipment.

There are many benefits associated with CTIS, the most visible being reduced consumption and time due to less slippage. Tyre wear and extended field time are also important. The most important is the preservation of the soil, which is an important factor for the yield. Please find details HERE.

Tubes - whether rubber or metal - on the outside of the wheel are a standard and reliable way to get air to the tyre. On the bar axles, we have developed an internal rotating union which makes it more discreet and easier to use with duals.

Yes! CTIS is meant to be used on demand, or "on the move” and with no speed limit." Using while in motion is safe.

FEEDBACK FROM OTHER FARMERS ***

Equipment is becoming heavier, faster, and more powerful. Fields are farther apart. Roading needs higher pressures to deal with the heat, weight and speed, while field work requires the lowest possible pressure to ensure maximum traction and minimal ground pressure. Being stuck at one pressure generates disadvantages - learn how CTIS can help you.

CONTACT OUR CTIS EXPERT

* Based on a field study carried out under real-life conditions in Scotland in 2016 using a Fendt 939 tractor fitted with Axiobib IF650/65R34 and Axiobib IF710/75R42 tyres and a Stewart three-axle trailer fitted with Cargoxbib HF 600/55R26.5 tyres. Soil test conditions: heavy blue clay. Also based on a field study carried out under real-life conditions in France in 2017 using a Fendt 724 Vario tractor fitted with MICHELIN Machxbib 710/55 R30 and MICHELIN Machxbib 900/50 R42 tyres and a GYRAX BMXL 240 trailer fitted with Cargoxbib HF 710/50 R26.5 tyres. Soil test conditions: clay-limestone. Actual results may vary depending on soil and weather conditions.

** Based on TERRANIMO calculations and a field study carried out under real-life conditions in France in 2020 by Bern University of Applied Sciences, School of Agricultural, Forestry and Food Sciences HAFL, at Michelin’s request, using a JOHN DEERE 7310 tractor fitted with MachXBib 600/70R30 and MachXBib 710/70R42 tyres and a THIEVIN three-axle trailer fitted with TrailXBib 650/55R26.5 tyres. Actual results may vary depending on soil and weather conditions.

*** External study commissioned by Michelin and carried out by "Tyre check" in Q4 2021 on the European geographical perimeter.